AEROSTRIP® Perforation Styles

The polyurethane membrane is perforated with needle holes to allow the supplied air to exit the diffuser body. The type of perforation has a significant impact on the operating range, i.e. the air flow rate of the aerator. With AEROSTRIP® diffusers you can choose between different types of perforation.

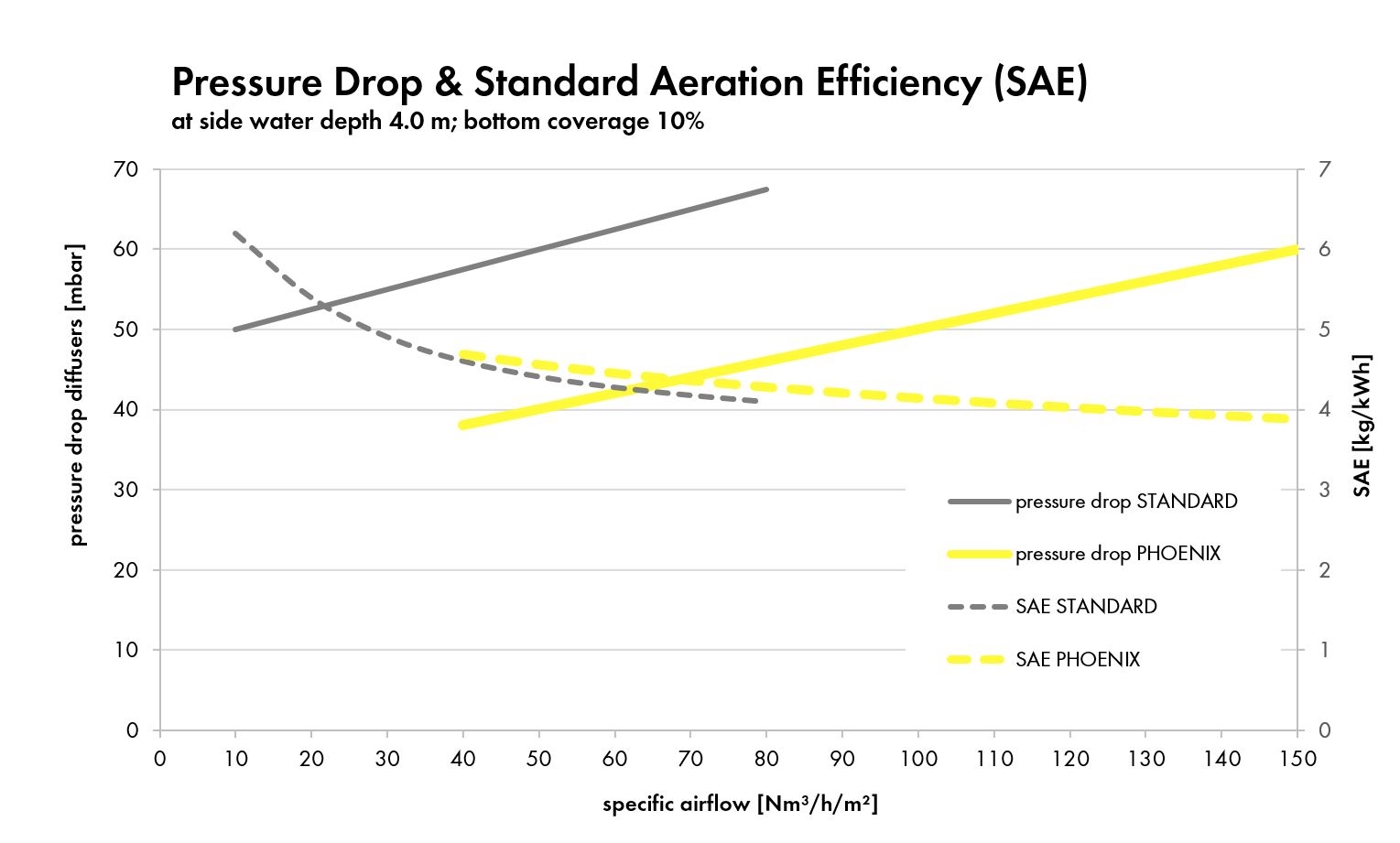

The “STANDARD” perforation has slightly smaller holes but a higher number of holes (approx. 400,000 holes/m²). It is particularly suitable for operation with low to medium specific airflows and achieves very high values for oxygen uptake (SOTE) and oxygen yield (SAE).

The “PHOENIX” perforation has slightly larger holes but a smaller number of holes (approx. 133,000 holes/m²). This results in a lower pressure loss and allows an efficient working range with specific airflows above 40 Nm³/h per m² of membrane area.